PurinElas - TDI Elastomers

TDI Elastomers

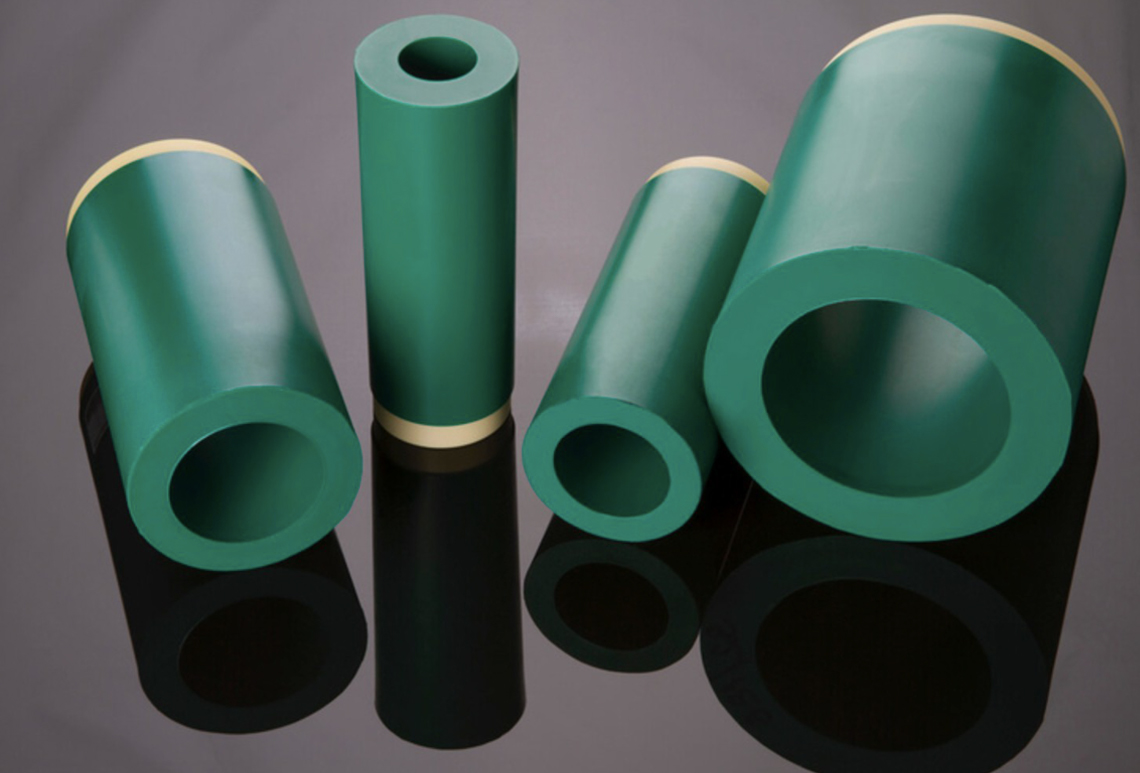

TDI Elastomers, a hot cast polyurethane prepolymer, are used in the most demanding applications where high performance is required.

These type of elastomers are obtained with TDI-based prepolymers and amines or mixtures to be used in equivalent ratios at temperatures between 100-150oC with 12-24 hours waiting times.

Polyester/TDI and Polyether/TDI are generally used in their formulations. Raw material selection and hardness selection should be made according to the place to be applied.

TDI Elastomers are generally in solid form due to their structure. In order to liquefy the prepolymers, they must be melted before application.

They have good mechanical properties such as superior abrasion resistance, high flexibility, high load carrying capacity, shear, tear resistance, chemical resistance and hydrolysis resistance.

Industrially, these products are widely used in the mining, industrial tires, pallet truck wheels, coatings, pressure rollers and metal fabrication markets.

We can summarize the differences between TDI and MDI elastomers as follows;

Quick Links

Contact an expert

Ayşenur DEDE

adede@purin.com.tr

Contact an expert

Simge UZUNER

suzuner@purin.com.tr

PurinElas Products

Top Market

Brochure

| TDI Elastomers | MDI Elastomers |

|---|---|

| Not sensitive to moisture | Very sensitive to moisture |

| Easy to mix | Care should be taken to mix |

| Manufacturing is not so critical | Require precision manufacturing |

| Up to 85D Shore hardness | Have a very wide hardness range |

| Short reaction time (cure) | Sometimes long reaction time (cure) |

| Not very sensitive to Cure parameters | Very sensitive to Cure parameters |

| Pot life and demoulding time difficult to adjust | Easy to adjust pot life and demoulding time |

| Mixture viscosity increases slowly | Mixture viscosity increases rapidly |

| TDI Ester | TDI Eter |

|---|---|

| Main Features | Main Features |

| Excellent abrasion and tear resistance | High abrasion resistance |

| Low compression set | High resilience |

| High resistance to chemicals | Excellent hydrolysis resistance |

| Easy processing (production) | Excellent behavior at low temperature |

| Good tensile strength | |

| Easy processing (production) | |

| Low compression set | |

| Applications | Applications |

| Tires | General purpose applications |

| Wheel casting | Wheel casting |

| Pipeline inspection indicators | Cushion pads |

| Scrapers | Springs |

| Cutting pads | Industrial rollers |

| Squeegees / Windshield wiper | Seals |